Price 2500000.0 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

Specification

- टाइप करें

- WHEAT CLEANING PLANT

- मटेरियल

- Mild Steel

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- ड्राइव टाइप

- वोल्टेज

- वोल्ट (v)

- वारंटी

- 1 Year

- सतह की फ़िनिश

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- महीने

About

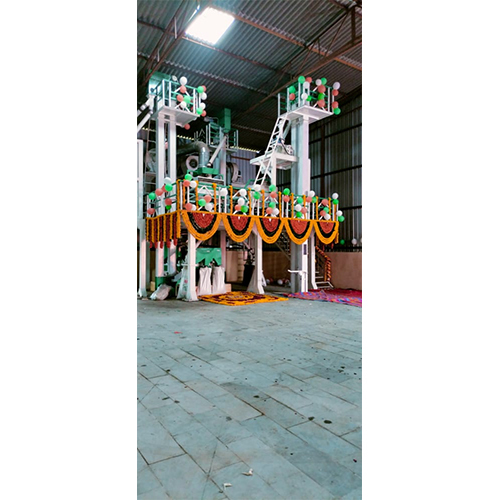

THIS PLANT IS USED TO CLEAN ALL THE GRAIN AND SPICES LIKE WHEAT, CHANA, MILLET, BARLEY, PADDY, CORN, CUMIN SEEDS, FENNEL SEEDS, MUSTARD, AJWAIN ETC TO CLEAN IT BY REMOVING BIG STICKS, STONES, BLACK SAND AND HOLLOW GRAINS ETC ALL IMPURITIES. THIS PLANT AQUIRES VIBRO MACHINERY, WHICH IS LATEST THESE DAYS. IT ENSURES SMOOTH OPERATION AND BEST RESULT.Advanced Cleaning Technology

This wheat cleaning plant integrates automated controls with a computerized system to ensure precise impurity removal, safeguarding the integrity of your grain supply chain. Its robust construction and polished finish guarantee longevity and ease of maintenance.

User-Friendly Operation

With fully automatic features and a PLC control system, operators can manage the cleaning process effortlessly. The electric drive enhances energy efficiency, making the plant suitable for high-volume wheat processing industries seeking consistency and minimal downtime.

FAQs of WHEAT CLEANING PLANT:

Q: How does the wheat cleaning plant operate automatically?

A: The wheat cleaning plant utilizes a PLC control system combined with computerized automation. This integration allows the machine to automatically manage the cleaning process, reducing the need for manual intervention and ensuring consistent, high-quality results.Q: What are the main benefits of using a wheat cleaning plant with mild steel construction?

A: Mild steel lends enhanced strength and durability to the plant, while the polished finish provides resistance to corrosion. This ensures long-lasting operation, minimizes breakdowns, and reduces maintenance costs.Q: Where can I purchase this wheat cleaning plant in India?

A: This wheat cleaning plant is available through reputable manufacturers, suppliers, and traders across India. You can contact them directly to discuss specifications, pricing, and installation services as per your requirements.Q: What is the process followed by the wheat cleaning plant?

A: The plant uses an automated sequence where raw wheat is fed into the system, impurities and foreign matter are separated through mechanical and computerized sorting, and clean wheat is discharged, ready for further processing.Q: How does the warranty system work for this wheat cleaning plant?

A: The wheat cleaning plant is backed by a one-year warranty which covers manufacturing defects and provides technical support. Warranty terms may include repair or replacement of defective parts within the specified period.Q: What is the plants voltage requirement and drive type?

A: The wheat cleaning plant requires an electric connection in the range of 220-440 Volts. It is powered by an electric drive, ensuring stable and efficient performance for large-scale wheat cleaning tasks.Q: Who is the ideal user of this wheat cleaning plant?

A: This plant is ideal for flour mills, grain processing units, and agricultural enterprises that need automated, high-capacity wheat cleaning solutions, particularly in markets where quality and efficiency are key priorities.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese